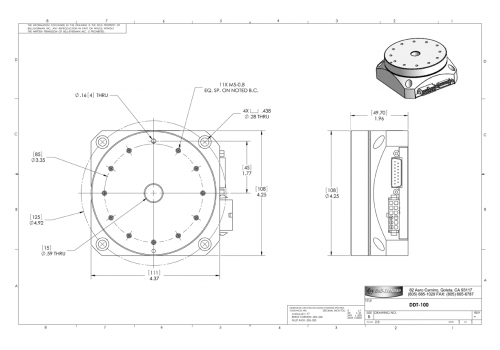

Direct Drive Theta

Low-profile stages for precision positioning and metrology

Our Direct Drive Theta (DDT) rotary stage units feature a compact mechanical design that makes them easy to integrate into metrology systems and other machines that need precision positioning.

- Low Profile, Large Through Holes. DDT units are available in two sizes, both with ample space in the middle to bring power and utilities to the top of the stage. The DDT 100 offers a 15 mm through hole, and the DDT 200 has a 50 mm through hole. Both units are less than 50 mm tall.

- Precise Angular Alignment. DDT rotary stages provide superb angular alignment capabilities. The DDT 100 model has an accuracy of ± 12 arc-sec, while the DDT 200 models have an accuracy of ± 6 arc-sec. Both units have a bi-driectional repeatability of ± 1 encoder count.

- Consistent Motor Tuning. DDT units have been engineered with extremely fine preload adjustments, which allow users to maintain consistent motor tuning.

- Ease of integration. DDT models install with just a four-bolt connection. Top plates can be configured to user specifications. The DDT 200 additionally offers three-point adjustable leveling mounts with mechanism for tip, tilt and elevation adjustments.

- Rugged. DDT features anodized aluminum construction with stainless steel hardware.

Register for access to additional engineering resources