Cartesian Robots for Every Travel Length

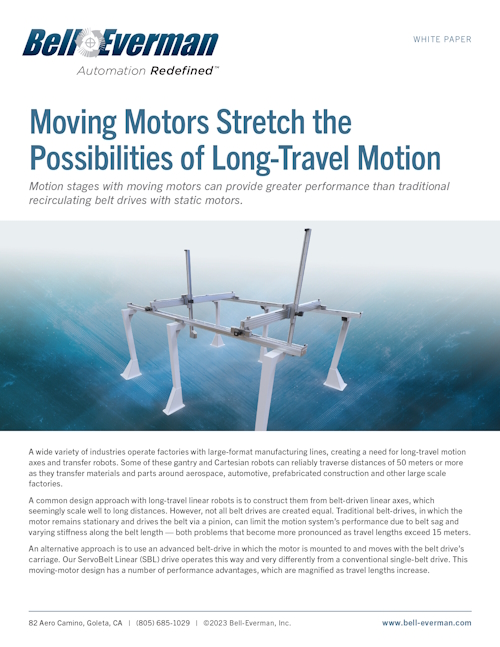

Linear robots, whether gantry robots or other Cartesian designs, can deliver precise, smooth motion and excellent load-bearing capabilities required by advanced automation systems. With configurations ranging from single- to multi-axis, linear robots offer a design flexibility that can address a wide range of automation tasks — from long-travel transfer robots to small precision motion stages. In many cases, linear robots can even replace multiple six-axis articulated arm robots, reducing the total cost, footprint and deployment time for automation systems.

Performance Advantages

Available in XY and XYZ multi-axis configurations, linear robots offer important performance advantages compared to automation solutions built around six-axis robots.

Multiple, Independent Carriages. ServoBelt™ Linear supports multiple, independently-controlled carriages on the same axis. This approach enables complex motion tasks on a single linear axis and can reduce the need for additional linear robots.

Long Travel Lengths. Expansive shop floors challenged with transporting parts and materials long distances are ripe for linear robot automation. Gantry systems designed with our ServoBelt™ Linear architecture have no length limitations — easily reaching 100 meters or more. Covering this distance with multiple six-axis robots is expensive and cumbersome.

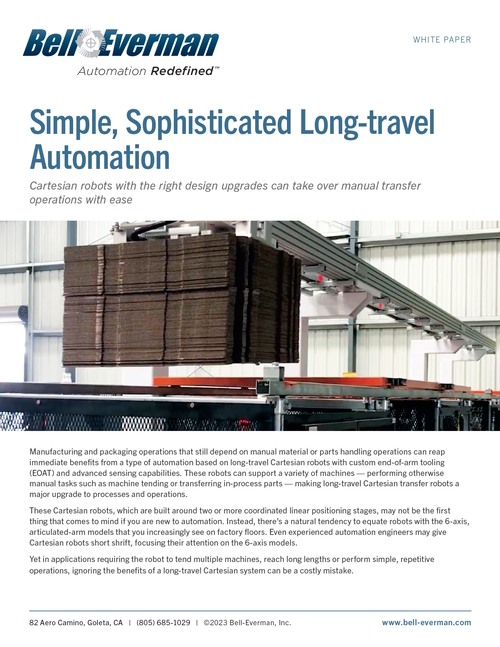

Machine Support. Mounting linear robots above or behind the machines they tend opens up space in tightly packed work areas. Additionally, this configuration frees up room for machine operators. To ensure proper machine support, we offer flexible mounting configurations as standard, including floor-mount stanchions and lifts as well as wall- and ceiling-mount toe clamps.

Application-Specific Tooling. Attaching custom end-of-arm tools (EOAT) to a linear robot expands its functionality. Instead of standard off-the-shelf grippers and vacuums, we design purpose-built EOAT for specific tasks that cannot be performed by off-the-shelf end effectors. Custom EOAT enables a linear robot to handle goods more effectively and perform more complex functions than many six-axis robots.