We can combine our standard motion stages into unique, higher-level automation systems.

Think of us as an extension of your engineering department.

Using our standard linear and rotary positioning stages as building blocks, we can create unique, cost-effective automation solutions that meet your application’s requirements. These engineered systems are larger and more complex than our standalone motion stages and incorporate controls, critical safety features and custom components—all delivered as one turnkey package.

From gantry-mounted electromechanical assemblies, to cartesian robots with extended travel lengths, our engineered solutions are tailored to your needs. While our standalone stages must fit within a predefined physical space and tie into your machine’s motion control system, these larger turnkey systems free us up to optimize all aspects of assembly and controls integration.

Featured Systems

Long-Travel Transfer Robot

Used in an agricultural packaging plant, this long-travel Cartesian robot has a travel length over 50-ft and is based entirely on our ServoBelt™ Linear Heavy linear stages. To deliver sheets of corrugated cardboard into four tray-forming machines, The robot rides over the top of the tray formers, which turn out up to 35 trays per minute. This turnkey system included controls development and custom end-of-arm tooling capable of handling 50-kg payloads.

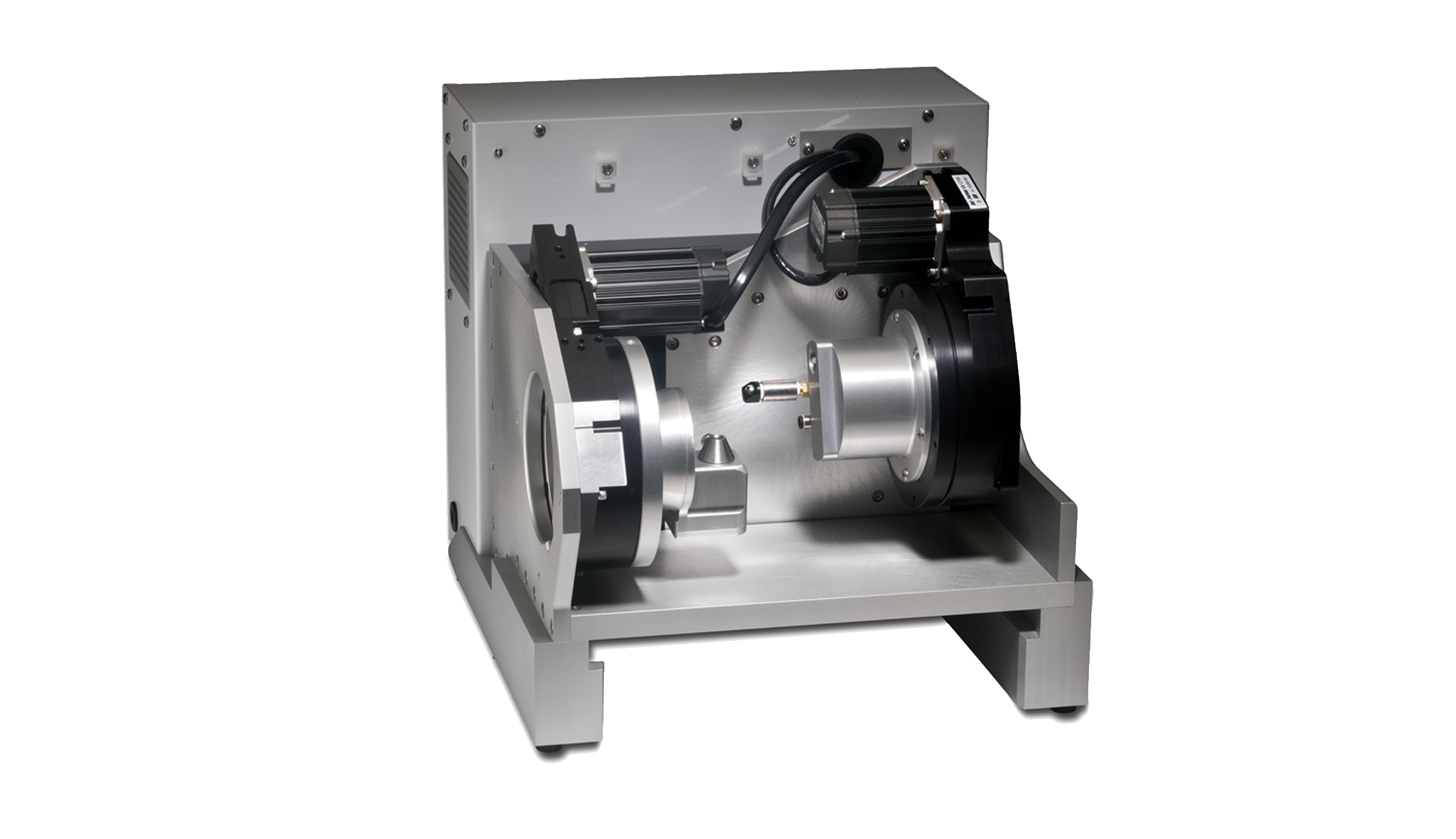

Specialized CNC Mill

Built to machine precision parts for a biomedical application, this custom CNC milling unit is built around our ServoBelt Rotary stages, whose smooth motion eliminates the chatter you would expect from linear ball screw actuators. The project included the development of a specialized control system that position the workpiece and tool using polar coordinates.

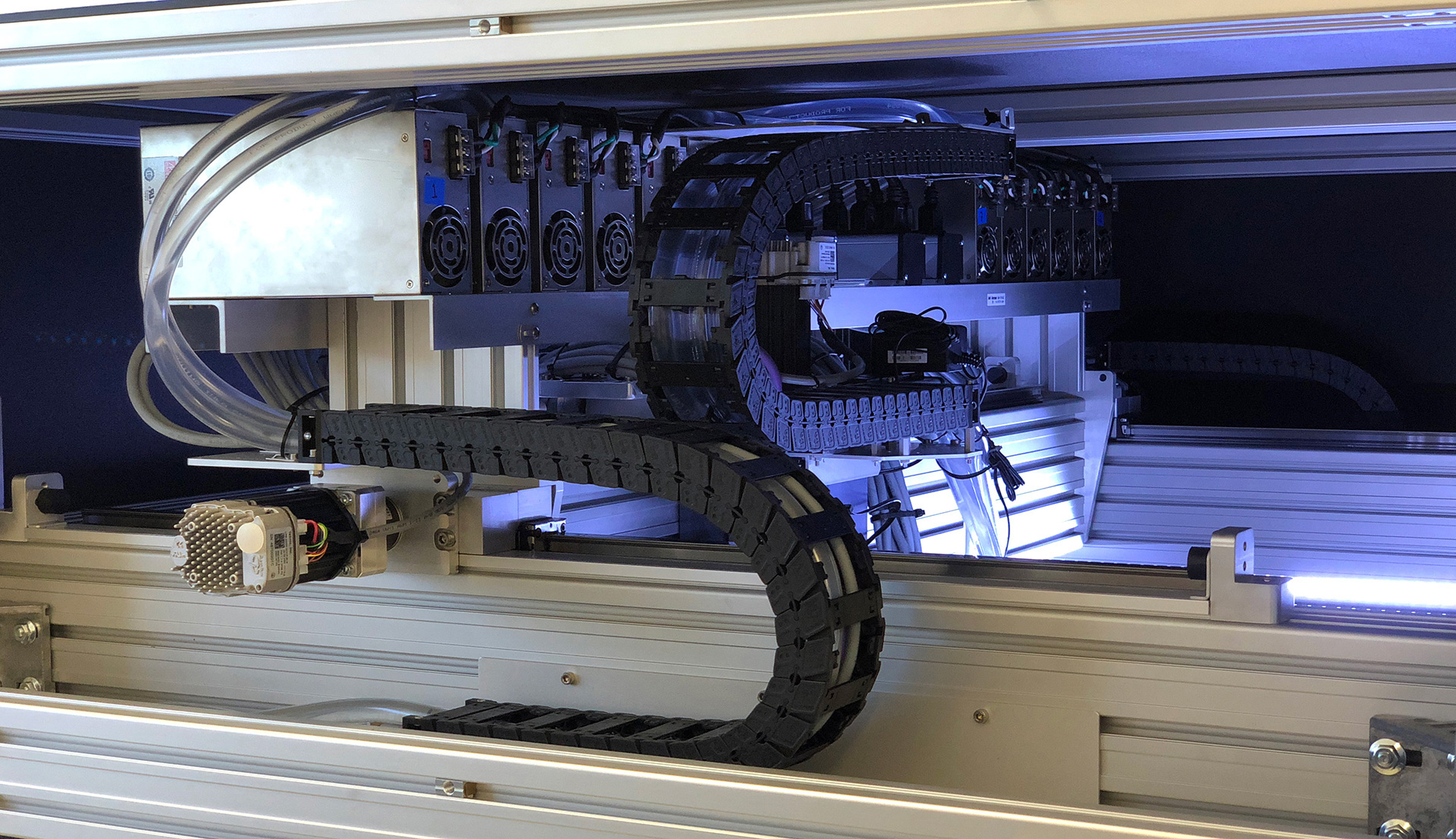

Solar Cell Cartesian System

Using our linear stages as the foundation, we engineered an x-y-z cartesian system for an application that measures solar cell efficiency. Our design addressed a number of challenging customer requirements—as the test system is fully enclosed, includes very bright LED modules and incorporates numerous electrical and cooling lines.

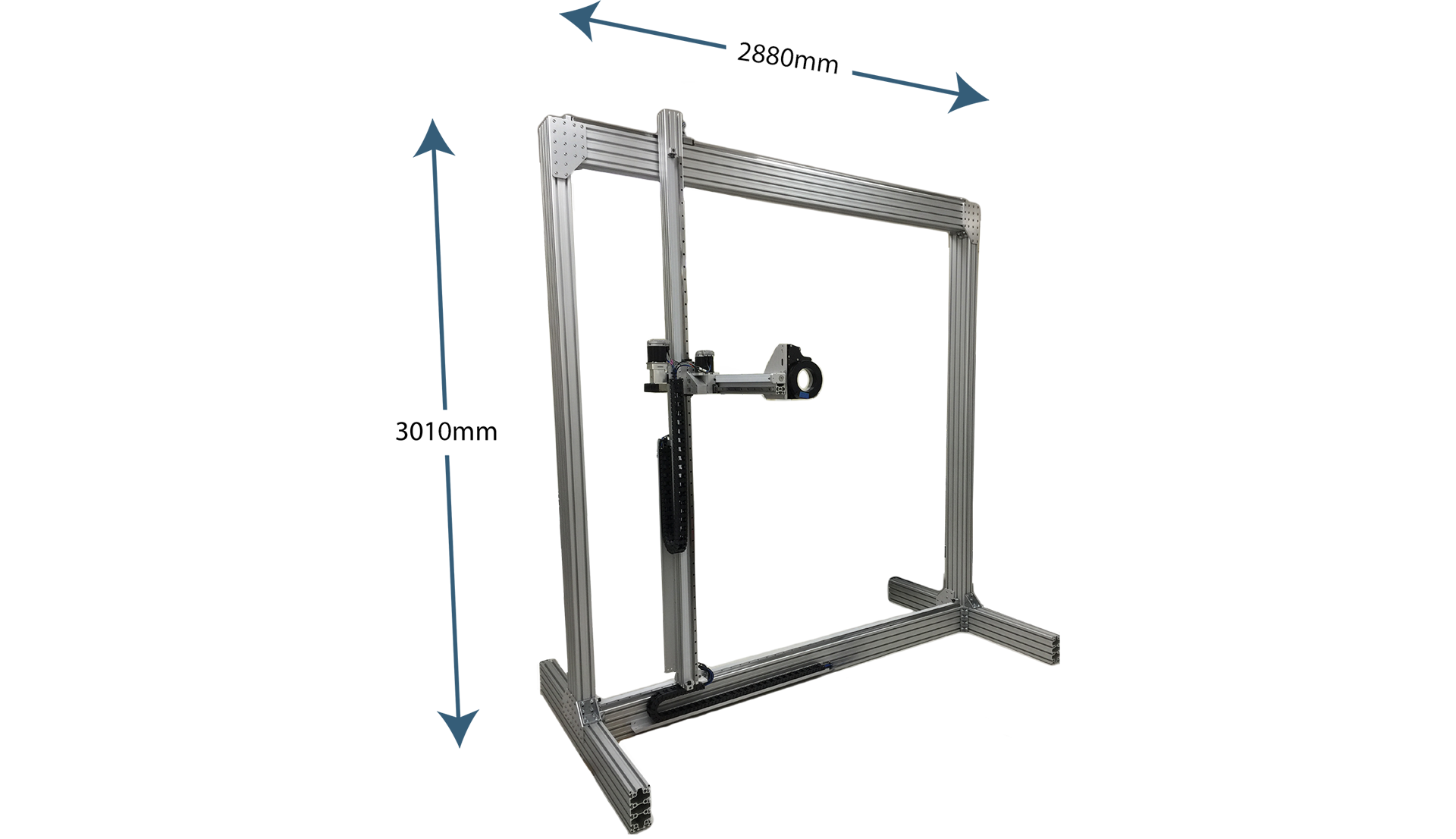

Vertical Gantry with Rotary

Engineered for a test and measurement application, our vertical gantry system incorporates ServoBelt Linear Medium stages with two different chassis sizes, as well as a ServoBelt Rotary 100 unit that provides an additional rotational axis at the end of the secondary horizontal axis. This 3 x 2.8-meter system avoids the pitfalls associated with traditional H-shaped gantry designs, including bridge deflection, positioning errors and high costs.

Your Advantages

Using our standard linear and rotary stages as automation building blocks has its benefits—especially compared to costly, more complex robotic systems.

- Faster time to market. Combining and extending our ServoBelt™ Linear series and other standard motion stages can shave weeks or even months off the development time of a complex machine.

- Lower costs. Our engineered solutions integrate commercial off the shelf (COTS) components wherever possible to keep your costs down. With full control over safety, assembly and controls integration, we also remove unnecessary layers and materials—frame extrusions, for example—which cuts down on labor and your overall bill of materials. Cartesian systems created from our ServoBelt and LowBoy Linear Stages are also a more capable, less costly alternative to 6-axis and SCARA robotic systems.

- Heavier payloads. Our turnkey solutions move heavy payloads at a fraction of the cost of other robotic systems. In one case example, our ServoBelt Linear cartesian robot replaced four SCARA robots on an agricultural packaging machine—easily meeting the 50-kg payload requirements at a quarter of the price.

- Unlimited sizes. Ideal for large-scale systems, our ServoBelt Linear series supports unlimited travel lengths—thanks to a unique splicing methodology that lets us join multiple sections of the chassis. A single axis also supports multiple carriages with independent motion—making it easy to create cartesian motion systems, gantry robots and other multi-axis configurations.

- Enhanced safety. Combining our linear and rotary stages into higher-level systems allows us to integrate light curtains, e-stops and other critical safety components. These assemblies are also safer by design—occupying spaces your operators wouldn’t need to enter.

- Custom components. Our engineered solutions typically involve custom design engineering work at the component level. If your assembly requires specialized end-of-arm tooling, for example, we’re ready to hit the drawing board.