All About Cantilever and T-Formation Gantries

As part of our series on gantry robots, our last blog post took a deep dive into two important gantry types — the I-formation (I-form) and H-formation (H-form) gantries. Now, let’s dig into cantilever and T-formation (T-form) gantries, along with their features, use cases and design criteria.

What Is a Cantilever Gantry?

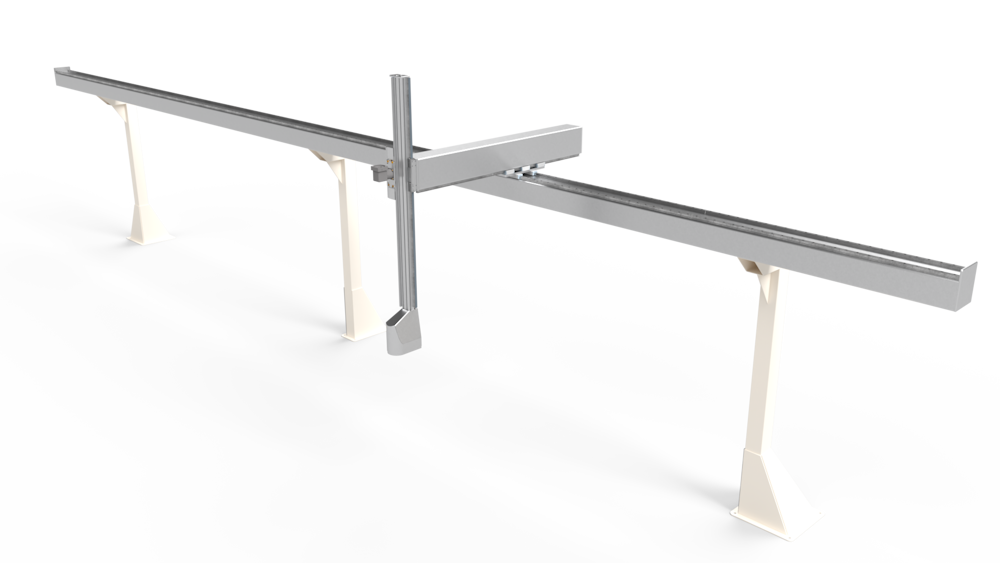

The cantilever gantry requires the least amount of hardware for a three-axis motion system and has a similar orientation to the H-form gantry, which consists of two base axes, a bridge axis and sometimes a Z-axis. If an application allows, the cantilever gantry’s “bridge” can be cantilevered off of the singular base axis.

You can find cantilever gantries in applications where the cantilever axis travel is 2 meters or less. Common applications include:

- Machine tending

- Material handling

- Packaging applications

- Pick-and-place systems

- Palletizing and de-palletizing

- Multi-step process automation

In terms of design criteria, both the payload and cantilever axis travel lengths are closely related to how you should size the chassis/guide rail of three-axis systems. One compelling advantage of ServoBelt™ LoopTrack technology is the ability to add multiple cantilever/Z axes as needed, increasing throughput in the same footprint as a single cantilever axis system.

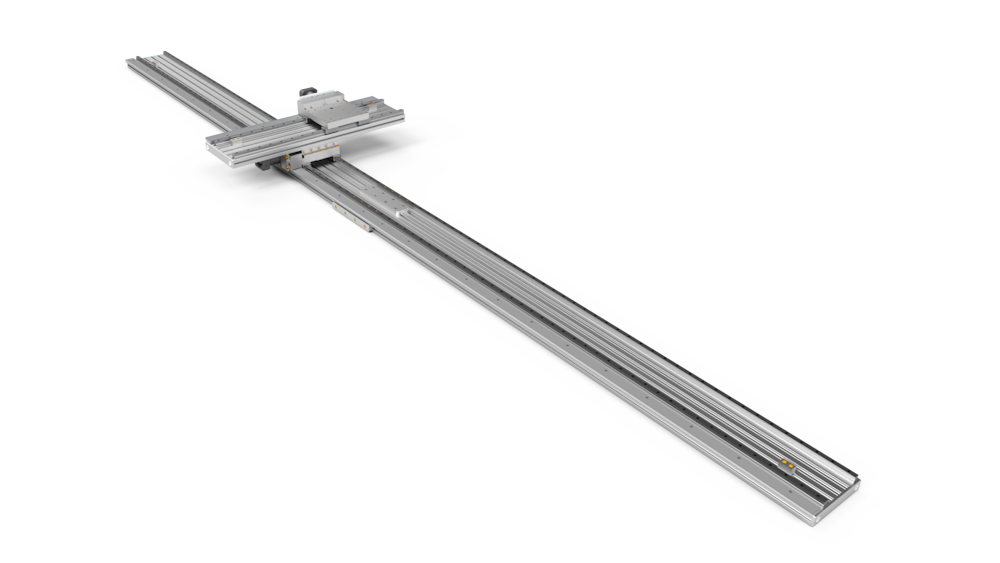

What Is a T-Form Gantry?

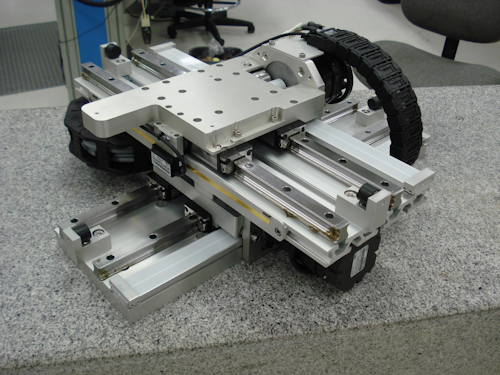

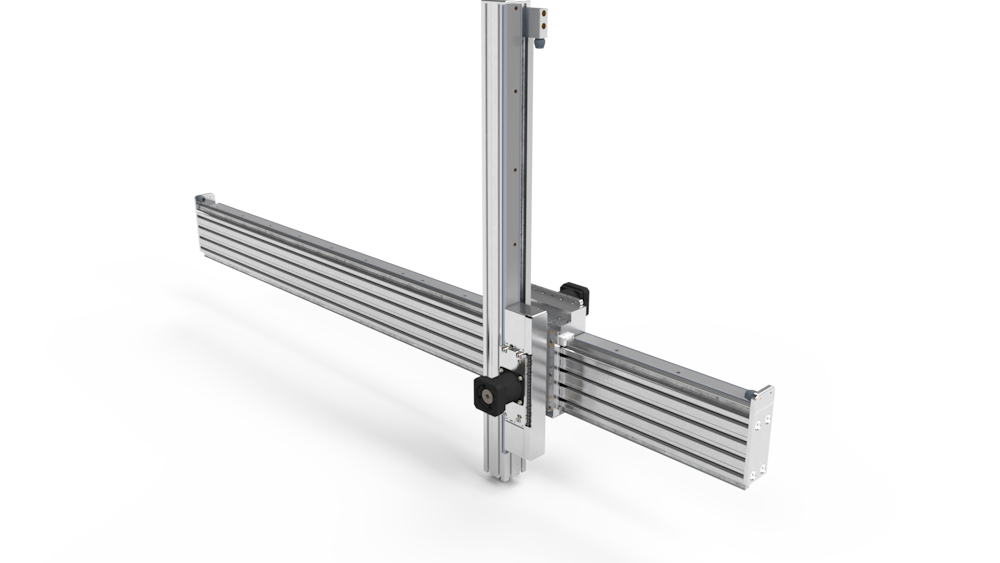

T-form gantries — which have the shape of a plus sign — are a minimalist setup in applications requiring movement in only two directions. This style can be oriented vertically or horizontally in both the XZ or XY directions, the latter of which is known as a “stacked” stage.

Stacked ServoBelt™ Linear Drives are suitable for high-speed pick-and-place, scanning and item transfer applications. ServoBelt offers a more open mechanism and enables high-fidelity bearing architectures, elevating their performance to a level typically associated with linear motor stages. However, unlike high-end linear motor drives, ServoBelt can support unlimited travel lengths and multiple, independently controlled carriages on the same motion axis.

In addition to these benefits, ServoBelt drives with LoopTrack technology let you easily add multiple Z or Y axes to your gantry system, increasing your throughput in the same footprint as a single Z or Y axis system.

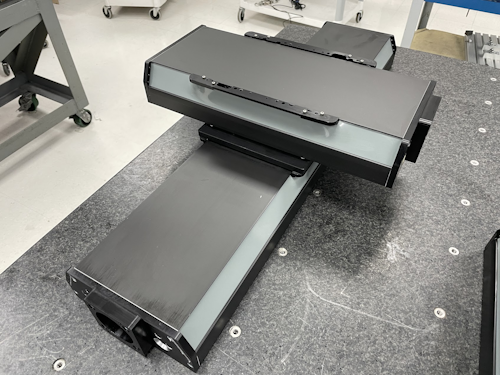

If your T-form gantry system calls for seals and travel lengths less than 1,500 millimeters (mm), LowBoy Linear Actuators are also available in high-precision, stacked XY configurations to support various metrology and inspection systems in semiconductor manufacturing and additive and subtractive manufacturing.

Other common use cases for T-form gantries include:

- Machine tending

- Article inspection

- Material handling

- Pick-and-place systems

- Palletizing and de-palletizing

- Process automation

- Additive manufacturing

- Semiconductor manufacturing

To learn more about cantilever and T-form multi-axis gantries, contact us today. You can also check out our online quotation tool to configure your own ServoBelt Linear system.