Press Releases

New ServoBelt™ Rotary Stages Cost Up To 50% Less

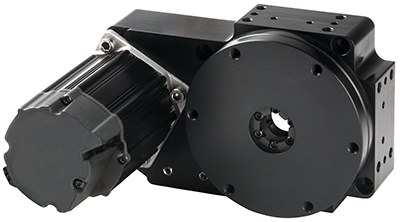

Goleta, CA – September 16, 2015 – Bell-Everman Inc. has developed a new type of belt-driven rotary stage that costs up to 50% less than the company's previous rotary stage designs.

The new rotary stages offer all the precision and technical performance of the company's original ServoBelt rotary stages. The only difference is that the new rotary stages have smaller through holes.

The new rotary stages offer all the precision and technical performance of the company's original ServoBelt rotary stages. The only difference is that the new rotary stages have smaller through holes.

Available with 16- and 25-mm through holes, the new ServoBelt rotary stages address the broad range of rotary motion and rotary table applications that don’t need to pass large bundles of utility connections through the center of the stage.

Shrinking the through hole allowed Bell-Everman engineers to simplify the design of the stage's angular contact bearings without affecting accuracies, speeds, load capacity or lifecycle expectations. The bearing simplification resulted in the bulk of the cost reduction.

For those applications that do require a large center opening, the company's original ServoBelt rotary models offer 50-, 100- and 200-mm through holes. Bell-Everman also offers a direct drive stage, the DDT, for ultra-high-precision positioning applications.

For more information, please visit www.bell-everman.com.