Explore Some of Our Latest Custom Automation Systems

Using our ServoBelt™ stages and actuators, we can design and deliver a linear or rotary positioning solution that fits your performance requirements. Here are some examples of systems we recently made:

Biomedical Gantry

This custom biomedical gantry features our ServoBelt Linear (SBL) Light Duty actuator. We designed this system according to our customer's specifications and turned it around quickly. It also works exceptionally well with a single-sided drive of the bridge motion. Our SBL Light Duty actuator is a perfect fit for a lot of biomedical machines, which don't always need a heavy-duty actuator.

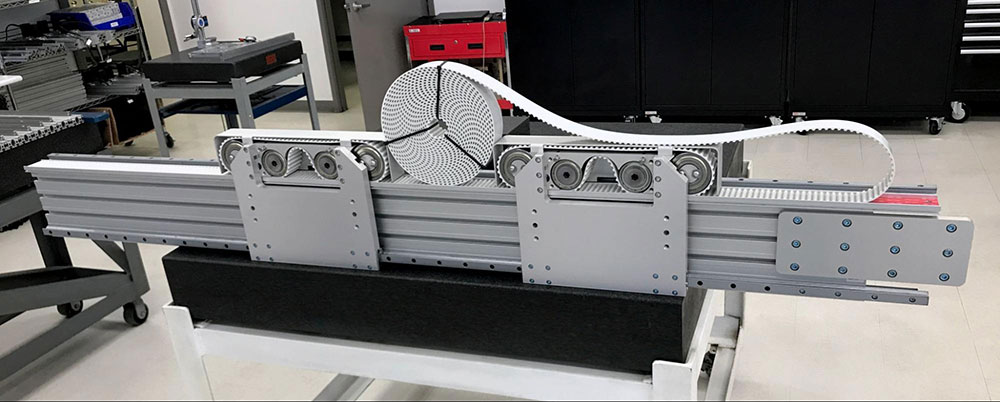

Two-Carriage Actuator for a Wet Bench

Next is this ServoBelt Linear Heavy LoopTrack (SBL-H-LT) actuator for a wet bench application. Thanks to its two-carriage design, we can control the movement of each carriage on the track independently. This is one of six sections that will total 39 feet in length once installed.

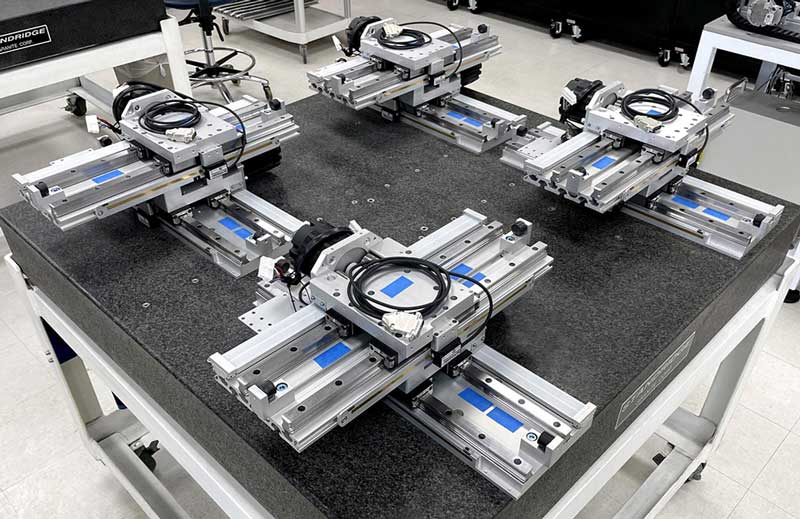

X-Y Stack for the Semiconductor Industry

Our ServoBelt Linear stages tackle some of the most demanding semiconductor applications. The following X-Y stacked stage, used in a singulation operation, can move an 80-pound mass 12 millimeters in 100 milliseconds, thanks to our control strategy that closes the servo loop on the linear encoder alone.

Light LoopTrack Model for X-Ray Inspection

An often-requested model, our ServoBelt Linear Light LoopTrack (SBL-L LT) actuator offers many of the same performance advantages as our SBL drive but is ideal for applications with lower force requirements. We've already shipped the first units for applications involving motion for large format X-ray inspection.

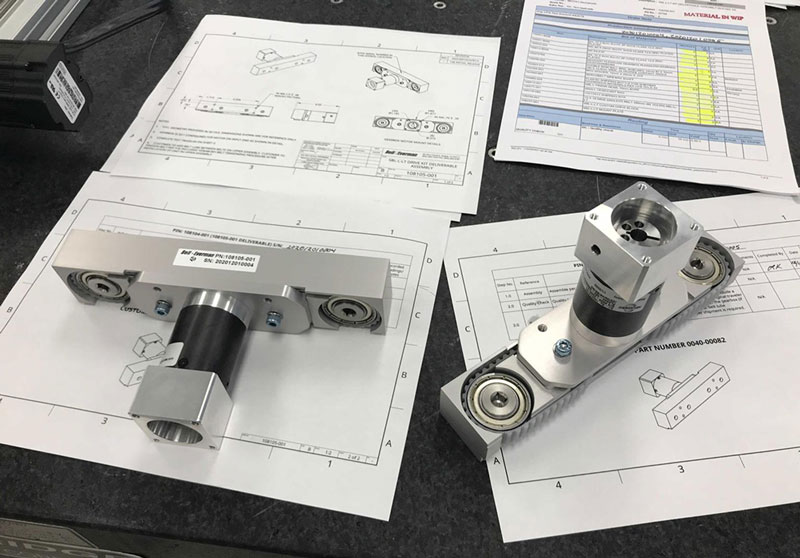

Rotary Stage With Pancake Motor

Our ServoBelt Rotary stages work great with many kinds of motors — including brushless DC pancake motors. Also known as printed armature motors and servodisc motors, pancake motors are a great fit for space-constrained applications. The implementation below uses a flat-armature design from Printed Motor Works to drive a SBR-16 stage mounted on granite. Its intended use is within the inspection envelope of a coordinate measuring machine (CMM), so space was at a premium. This motor extends only 26-mm from the mounting surface versus about 152-mm for an equivalent servomotor with a conventional frame design. Despite its compact size, this 94-W motor packs a punch with a peak torque of 3 Nm and a rated speed of 3000 rpm.

Configure Your Own System

Using our ServoBelt linear and rotary stages, we can design custom automation technology quickly according to your exact specifications. Ready to get started? Configure a system today.