Servonut LowBoy Moves Into Micromachining

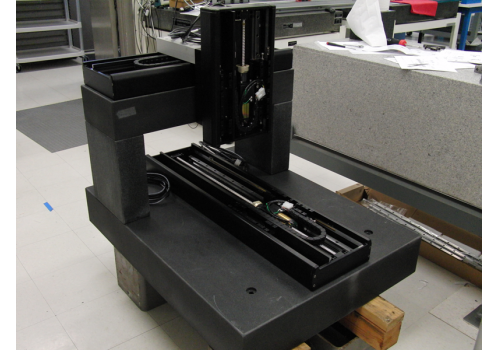

Our motion systems are often scaled up for large-format manufacturing applications, but we’ve recently taken our technology in the opposite direction to address miniature manufacturing. Case in point: We’re putting the finishing touches on a new 3-axis motion stage for a vision-guided CNC micromachining system.

With a work envelope measuring 690 x 450 x 150 mm, this micromachining stage has a large addressable area that might not seem “micro” at all. Yet with a positioning resolution of just 0.5 µm, the stage enables the machining of sub-micron features on larger workpieces.

The system is built around around a trio of our zero-backlash Servonut LowBoy linear axes, which incorporate Bosch-Rexroth precision-rolled ball screws and bearings. Renishaw linear encoders, Teknic Eclipse 545 amps and Emoteq motors round out the controls.

Together, these components add up to a CNC system that makes quick, accurate bidirectional moves without sacrificing the high-axial stiffness required for a steady machining spindle. In testing, our new micromachining stage has been making accurate 0.5 µm step moves with ease.

This particular stage represents just one of our on-going projects in miniature manufacturing. Sign up for our electronic newsletter to be the first to learn about another unique CNC micro machine that we have in the works.