Taking Advantage of ServoBelt™ When Designing Robot Transfer Units

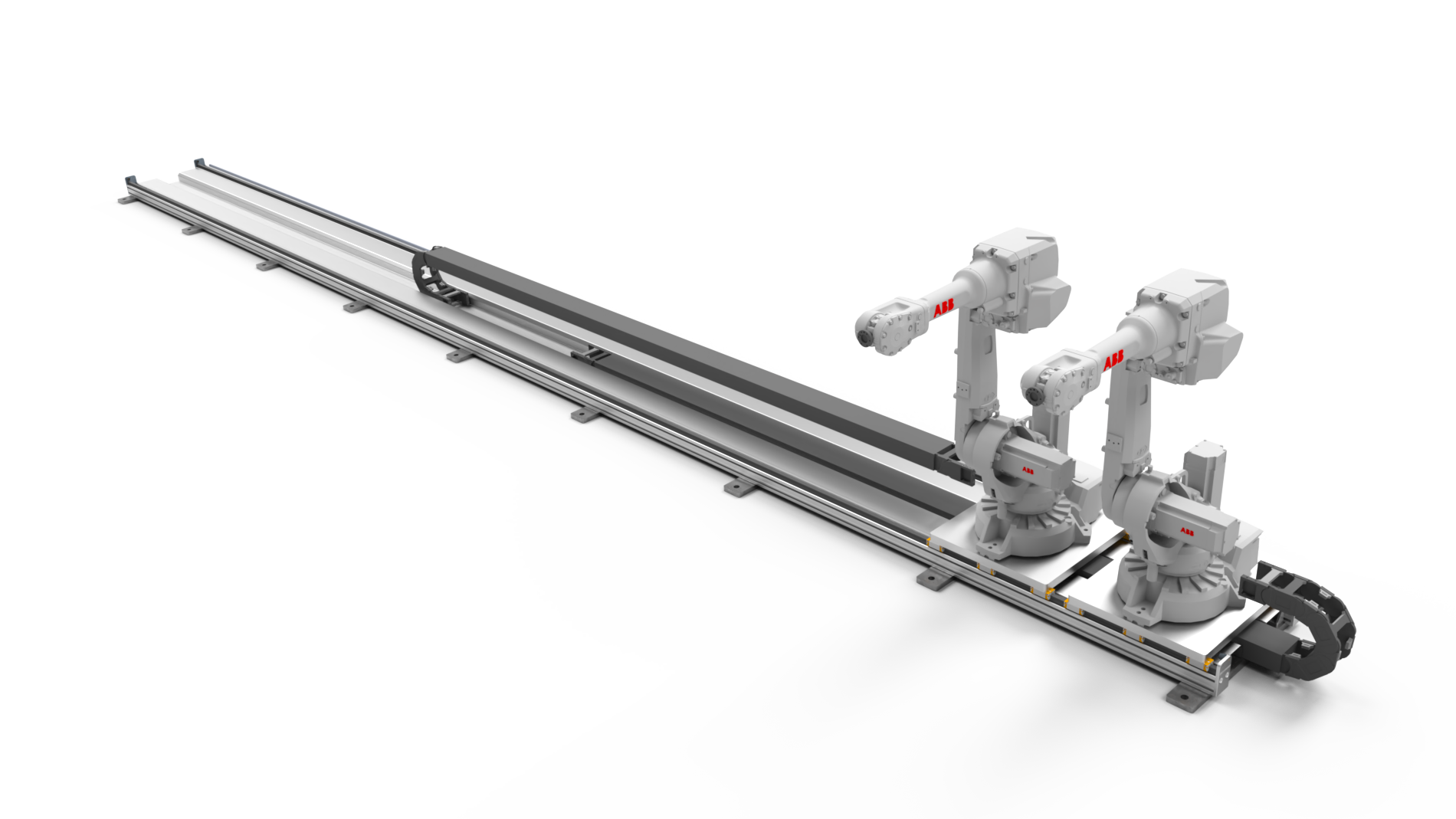

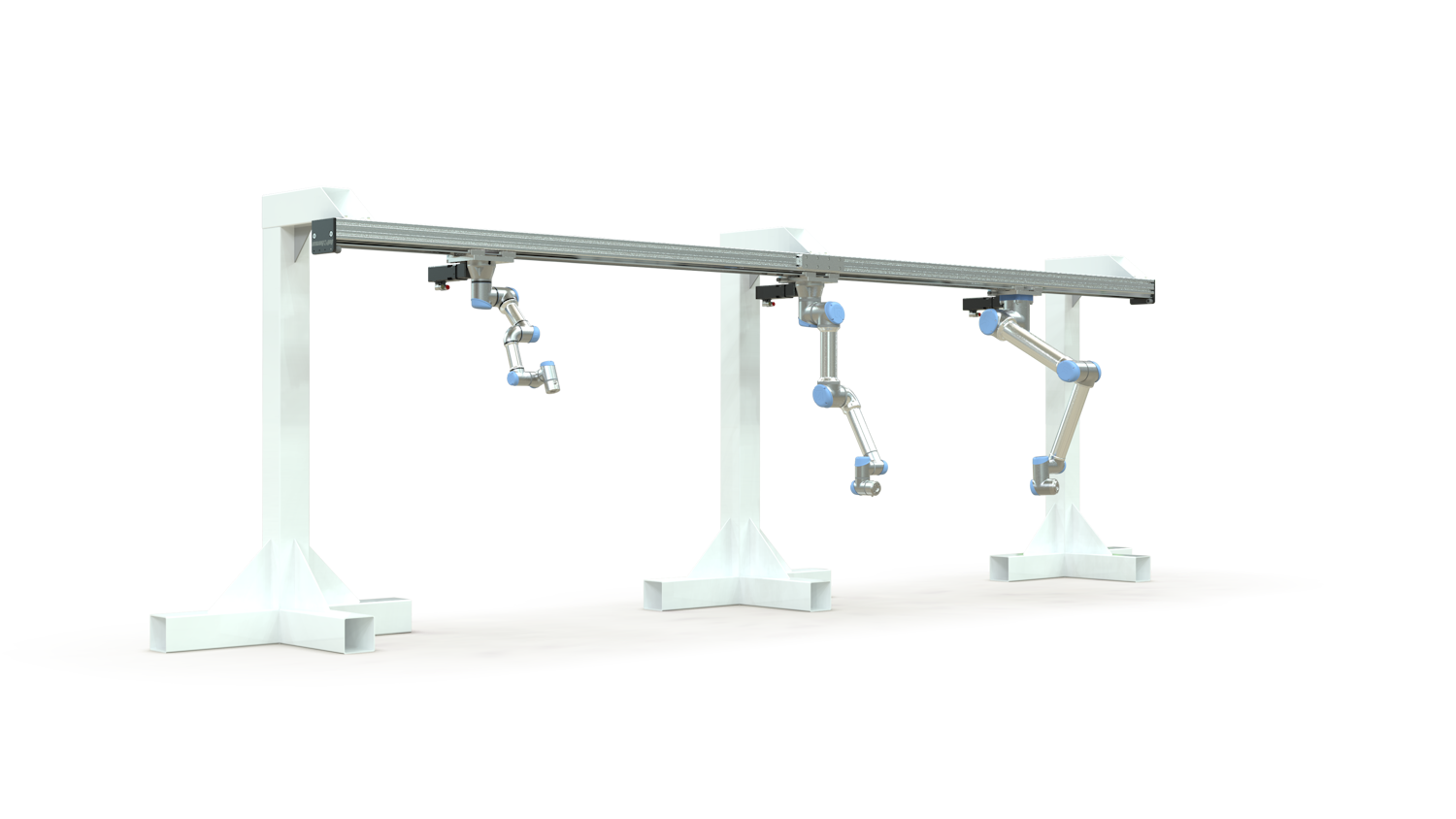

Robot transfer units (RTUs) are gaining ground — literally — in many industrial applications. These sophisticated motion systems transport articulated arm and collaborative robots (cobots) along a linear path, adding a seventh axis of movement and extending the robot’s work envelope. Thanks to this increased mobility, the robot can tend to multiple workstations or machines across wide swaths of the factory floor, unlocking a number of benefits.

For example, RTUs enable one moving robot to perform the work of many stationary robots, improving plant productivity without having to invest in additional costly robotic arm systems. They also accommodate floor, elevated and inverted mounting configurations, supporting more flexible factory layouts and enabling the RTU to be set up away from workers to increase safety.

RTU Design Methods

Without a doubt, RTUs are an excellent way to extend the reach of articulated arm robots and cobots. However, not all RTU design methods are equal.

The classical approach involves mounting the robot on a platform that runs along a linear track, the length of which will vary depending on the application. You also have many drive options to choose from, including belt drives, which offer inexpensive but low fidelity motion for a single carriage only, and rack and pinion drives, which offer a high payload capacity, but are costly if the goal is high precision.

At Bell-Everman, we can design these classical RTU systems to suit your needs, and to whatever fidelity desired. Redefining the classic belt drive approach, our ServoBelt™ Linear Drive supports unique RTU capabilities, making it a very compelling choice for 7th-axis systems:

Unlimited travel lengths. ServoBelt Linear’s chassis is based on standard Bosch-Rexroth T-slot extrusions. This feature, along with a unique splicing method that lets us join multiple sections of the chassis, supports RTU systems with unlimited travel lengths and limitless scalability. This splicing ability also avoids the performance and commissioning difficulties that can arise in long-travel applications that involve other motion technologies.

Multiple, independently controlled carriages on the same axis. Because a single ServoBelt Linear axis can support multiple, independently controlled carriages, we can design RTUs with multiple articulated robots and cobots running on the same motion axis.

Thanks to its limitless travel length and ability to support multiple, independent carriages on the same axis, ServoBelt shines in many common RTU applications. They include:

- Extending the work area of robots and cobots in manufacturing environments.

- Machine tools — e.g., moving castings or tending to injection molding machines.

- Improving the efficiency of tasks like drilling, welding, assembly, painting and more.

- Extending warehouse and packaging operations like palletizing, loading/unloading and transporting products.

To learn more about designing RTUs with ServoBelt, contact us today. You can also use our online quotation tool to configure your own ServoBelt Linear system.