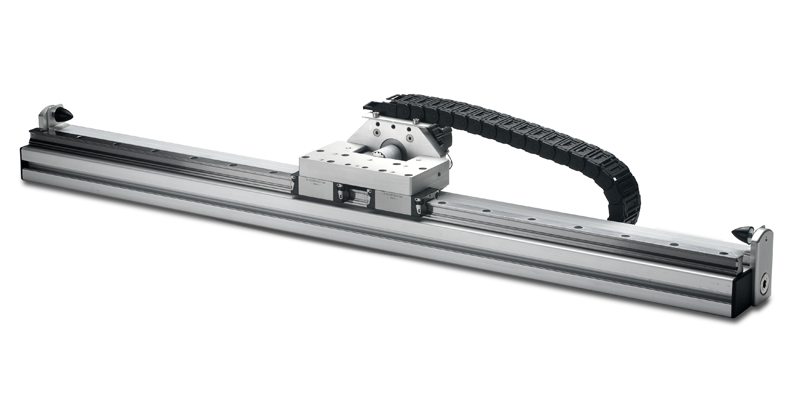

ServoBelt™ Linear Medium Still Ticking—At 50 Million Cycles And Counting

“How long does the belt last?” It’s one of the first questions we get when engineers look over our ServoBelt™ Linear stages for the first time. And it’s a natural question to ask since many engineers have had experience with a broken belt drive at one time or another.

Yet the answer for ServoBelt is that the belts don’t break during the intended life of the linear stage. What’s more, the belts don’t even degrade to the point that accuracy or repeatability change significantly. We’re confident in these claims not just from field reports but also from our own round-the-clock lifecycle and performance tests.

Long-Lasting Belt. In one of our ongoing tests, we’ve subjected one of our ServoBelt Medium linear stages to a move involving two start and stop points with a moving mass of 31.25 lb and a 1.6g acceleration (50 lb force).

We would consider this close to a “worst-case” move, given the applications for these linear stages. And even under these difficult conditions, the stage has run for more than 50 million cycles to date. It’s still going strong and hasn’t needed any maintenance yet, not even a belt retensioning.

Maintains Performance Too. Broken belts are painfully obvious, but another more subtle failure mode would be belt degradation. If the belt teeth degrade or undergo dimensional changes over time, you would expect the accuracy and repeatability of the stages to suffer. So we look very carefully for degradation effects too.

In our ServoBelt Medium test, for example, we’re not just counting cycles. We also measure repeatability over time. The results have been promising with the bi-directional repeatability coming in under 53 microns after 40 million cycles. That’s well within the repeatability range of ±25 to ±125 microns that we give for brand new ServoBelt units.

Not Really A Belt Drive. The key to ServoBelt’s longevity and stable performance lies in the unique way that we incorporate belts into the stage. Our belt drives function more like a rack-and-pinion than a traditional belt drive. They actually use two belts, a lower one adhered to the stage’s aluminum frame and the upper belt meshed with the lower one. A driven pinion in the carriage moves between the two belts, and only the two-inch portion of the upper belt that rides over the pinion is under tension at any given time. Portions of the belt not engaged with the pinion remain meshed and untensioned, which contributes to the long life. You can read more about ServoBelt Linear’s operating principles here.

Easy To Change If Needed. The bottom line about the belt life in our linear stages is that most applications won’t ever require a belt change because of wear or degradation. We have had customers change belts due to physical damage or contamination. We also recommend that you change the belt whenever you change the motor. If you do find yourself changing a belt, the process is easy and takes about 30 minutes. If you do find yourself changing a belt, the process is easy and takes about 30 minutes. You can learn how to replace the motor and belt in this video.

Our engineering team subjects all of our motion stages and actuators to demanding lifecycle and performance tests that simulate a variety of real world conditions. Fill out this form and we’ll send you a detailed report on our latest ServoBelt Linear test results.